Kitchen fire protection systems

of the highest quality

Kitchen fire industry experts

Solutions to protect people and property

Peace of mind

Technical experts and specialists in all areas of fire protection

Nationwide service

Providing a consistently high level of service across Australia

Commercial Kitchens

Commercial kitchens are a highly specialised fire risk environment, so it’s vital to protect property and people. Annually the destruction caused by kitchen fires cost millions of dollars in lost revenue and repairs. A kitchen fire risks the lives of staff and diners and costs tens of thousands of jobs.

Every aspect of our work is fully guaranteed and we maintain the highest standards.

What we offer:

- Supply and installation of Kitchen Hood Fire Suppression systems

- Semi-annual fire system maintenance inspections

- Commercial kitchen fire protection system design

- Repairs and upgrading of fire protection systems

- Hydrostatic testing of cylinders

- Upgrading of fire systems to meet AS3772-2008

- Wet chemical kitchen fire protection systems

- Our team has years of industry experience, and our skills are continually being refined and improved through ongoing training

- We only use high-quality products from names you know and trust

- We offer support throughout the entire process from design to procurement through to commissioning

- Service is always attentive and personal with one point of contact saving you time

- Full after-sales support service

RESULTS

Qantas Catering – Melbourne Airport

One of the largest Amerex ZD kitchen system installations in company history.

Sydney Fish Market

Nicholas Seafood, the Sushi Bar, Peter’s Fish Market, the Fisherman’s Wharf Seafood Chinese restaurant, the Fish Market Café and Christie’s Seafood all faced a similar problem — to provide kitchen staff and customers with reliable, swift and effective kitchen fire protection.

PROJECTS

Brisbane Convention & Exhibition Centre

The Brisbane Convention & Exhibition Centre has been named The World’s Best Convention Centre by the International Association of Congress Centres. It has 44 meeting rooms over 20,000 sqm of dedicated exhibition space. Delta Fire designed, installed, commissioned and maintained their Amerex KP Restaurant Fire Suppression System.

Brisbane International Airport

The airport handles 6.2 million passengers a year with 34 international destinations. Delta Fire designed, installed, commissioned and maintained their Amerex KP & ANSUL R102 Restaurant Fire Suppression Systems.

Cannington Mine

The Cannington mine in North West Queensland is one of the world’s largest producers of silver and lead. Delta Fire designed, installed and commissioned an Amerex KP Restaurant Fire Suppression System.

CBUS Super Stadium

Cbus Super Stadium is the Gold Coast’s premier sporting and entertainment venue. The 27,400 seat stadium is the home of the Gold Coast Titans NRL team and has also hosted rugby union, Nitro Circus and community events. Delta Fire designed, installed, commissioned and maintained their Amerex KP Restaurant Fire Suppression Systems.

Regional Processing Centre – Nauru, PNG

The Nauru Regional Processing Centre is an offshore Australian immigration detention facility, located on the South Pacific island nation of Nauru. Delta Fire designed, installed, commissioned and maintained their Amerex KP Restaurant Fire Suppression Systems.

Sheraton Resort -Tokoriki Island, Fiji

The Sheraton Resort is a five-star complex. Delta Fire designed, installed and commissioned an Amerex KP Restaurant Fire Suppression Systems.

St Vincent’s Hospital Kangaroo Point

Sydney Cricket Ground

Delta Fire designed, installed, commissioned ANSUL R102 Restaurant Fire Suppression Systems for the stadium that has a capacity city of over 44,000.

Sydney International Airport

The airport handles millions of passengers a year and connects to more than 90 destinations around the world. Delta Fire designed, installed, commissioned and maintained their Amerex KP & ANSUL R102 Restaurant Fire Suppression System.

Townsville University Hospital

The Hospital currently has 775 beds and supports a catchment of almost 700,000 people. Delta Fire designed installed and commissioned an Amerex KP Restaurant Fire Suppression System.

Wheatstone LNG Project

The Wheatstone Project in Western Australia’s Pilbara region is one of Australia’s largest resource developments. The foundation project includes two liquefied natural gas (LNG) trains with a combined capacity of 8.9 million metric tons per annum and a domestic gas plant. Delta Fire designed, installed, commissioned and commissioned their Amerex KP Restaurant Fire Suppression Systems.

University of Queensland

Delta Fire designed, installed, rectified and maintains Ansul Phirana Kitchen Suppression Systems throughout the University.

Gabba

Delta Fire designed, supplied and installed Amerex KP Kitchen Fire Suppression Systems in their kitchens.

Q Catering Melbourne Airport

Delta Fire provided a compliant wet chemical solution to replace the existing wet chemical system that did not meet the capacity required. The kitchen required modification of the existing fire alarm and fuel gas shut off systems in line with the establishment of the system.

Rod Laver Arena

Delta Fire designed, supplied and installed Ansul R102 Kitchen Suppression Systems across their kitchens.

MCG

Delta Fire designed, supplied, installed and maintains Ansul R102 Kitchen Suppression Systems across their many kitchens.

WHITE PAPERS

Amerex Strike Electronic Control System

Amerex KP & ZD Restaurant Systems Driven by a commitment to delivering the best for their customers, Amerex announce the addition of their STRIKE Electronic Control System (ECS) to their KP™ Restaurant Fire Suppression System. STRIKE has completed UL testing and is now available.

The Commercial Kitchen Fire Challenge – Protecting Property & People

Restaurant fires typically start in the kitchen. Annually they cost millions of dollars in lost revenue and repairs, risk the lives of staff and diners, and cost tens of thousands of jobs. However

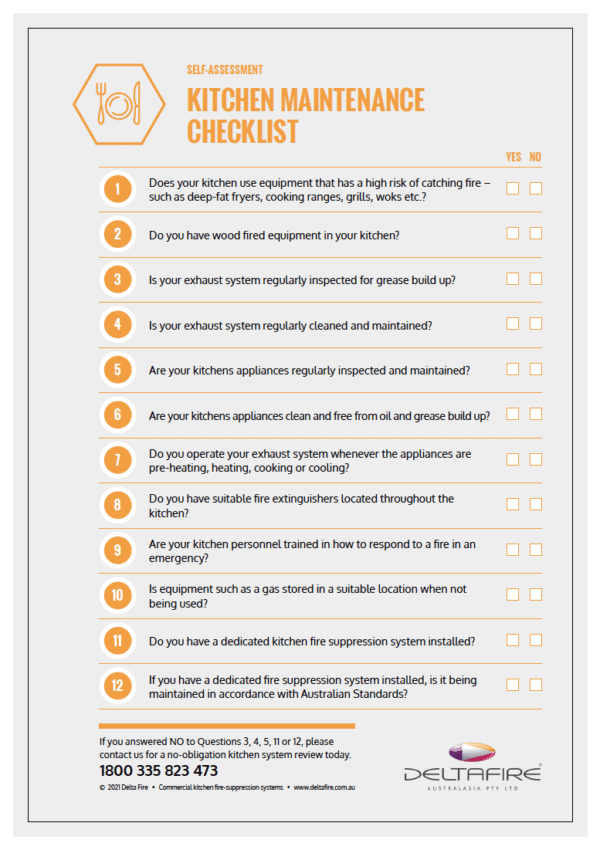

KITCHEN SAFETY CHECKLIST

Dale from Delta Fire runs through some quick and simple maintenance checks that you can do yourself to help your business avoid a fire.

KITCHEN MAINTENANCE CHECKLIST

Download our free 5-minute guide to help you recognise the fire risks in your commercial kitchen.